The story behind the supply chain game

The supply chain game is SoftDrinkGame’s version of a classic simulation, known as the beer game. This game lets you experience problems of supply chains.

This game was originally created in the 1960’s by Jay Forrester at the Massachusetts Institute of Technology (MIT). His game can be used to show the benefits of sharing information, supply chain management and working together in a supply chain.

In our supply chain game, we’ve taken the original game and developed it further to include some additional challenges that are common in supply chains.

The goal is to keep the supply chain costs as low as possible and your customers happy!

See the ‘How to play’ section, so you’re reading to start managing your supply chain.

How to play the supply chain game

Test your skills of running a supply chain with our online game. Can you complete the ordering process, without ending up with too much stock? Your profits and reputation are at stake!

You’ll manage the supply chain for one of Britain’s most popular items - tins of soft drink.

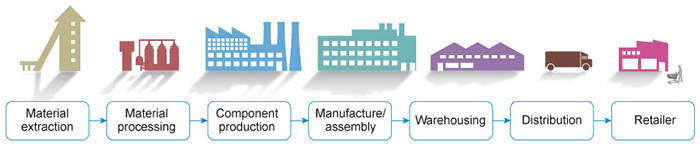

What does a supply chain look like?

Below is an image showing the different stages of a supply chain.

Playing the game

You make the important decisions, such as how much stock you order. Can you keep your customer happy?

You don’t need to worry about the deliveries to your customers - this is done automatically, but you’ll need to make sure you’re not hit with any fines. Every order must be completed. Backorder penalties will cost you £1.00 per unit.

Your main task is to minimise costs and maximise the customer service level. It sounds simple, but if you start to struggle, imagine what it’s like working for one of the leading supermarkets and looking after 90,000 different items!

The supply chain game dashboard

In the game dashboard you’ll see the key information to manage the supply chain.

This bar includes:

- The length of time you’re playing for.

- Your individual performance(with the total cost for the role you’re playing), plus

an indicator of how well you’re doing.

- The red section means you’re below average.

- The yellow section means you’re average.

- The green section means you’re above average.

- The supply chain performance(the total costs and stock in the supply chain), plus an indicator showing how well your supply chain is performing compared to that in a typical game.

How the game works

On the main part of the screen you will find a graphic representation of the supply chain that you are managing.

The material flow, which

covers the shipment of the product.

The material flow, which

covers the shipment of the product.In this supply chain you will observe two flows:

- the goods or material flow (soft drink) - flowing from left to right

- the information flows (orders) – flowing from right to left.

You furthermore observe:

Starting the game

To launch the supply chain game click ‘Finish’ on this screen and then ‘Play game’.

Good luck!

Supply chain performance

|

Factory

|

Wholesaler

|

Distributor

|

Retailer

|

|

|---|---|---|---|---|

|

|

|

|

|

|

| Storage cost |

£20

|

£55

|

£73.50

|

£91.50

|

| Shortage cost |

£1,536

|

£920

|

£729

|

£455

|

| Order variability |

203.45

|

112.37

|

45.07

|

3.65

|

| Total cost |

£1,556

|

£975

|

£802.50

|

£546.50

|

Factory

You have received an order...

Help

On the main part of the screen you will find a graphic representation of the supply chain that you are managing.

The material flow, which covers

the shipment of the product.

The material flow, which covers

the shipment of the product.In this supply chain you will observe two flows:

- the goods or material flow (soft drink) - flowing from left to right

- the information flows (orders) – flowing from right to left.

You furthermore observe:

| Period |

|---|

| Order received |

| Available inventory |

| Order placed |

| Order variability |

| Storage costs |

| Shortage costs |

| Product discarded |

| Period | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Order received | 100 | 100 | 100 | 99 | 97 | 113 | 135 | 159 | 147 | 172 | 173 | 163 | 154 |

| Available inventory | 120 | 120 | 40 | 20 | 20 | 160 | 80 | 200 | 200 | 230 | 200 | 100 | 72 |

| Order placed | 20 | 20 | 20 | 160 | 80 | 200 | 200 | 230 | 200 | 100 | 72 | 145 | 165 |

| Order variability | 0 | 0 | 0 | 0.01 | 0.09 | 1.68 | 12.95 | 44.32 | 63.19 | 107.55 | 151.56 | 182.43 | 203.45 |

| Storage costs | 10 | 10 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Shortage costs | 0 | 0 | 60 | 139 | 216 | 169 | 224 | 183 | 130 | 72 | 45 | 108 | 190 |

| Product discarded | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |